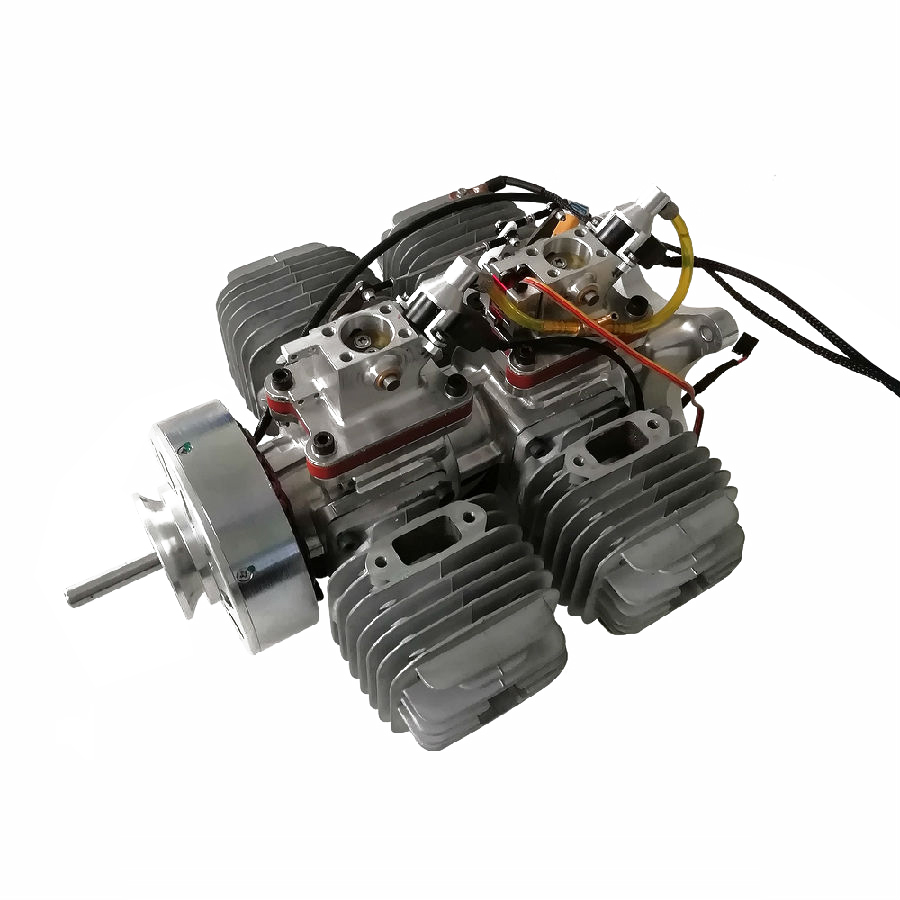

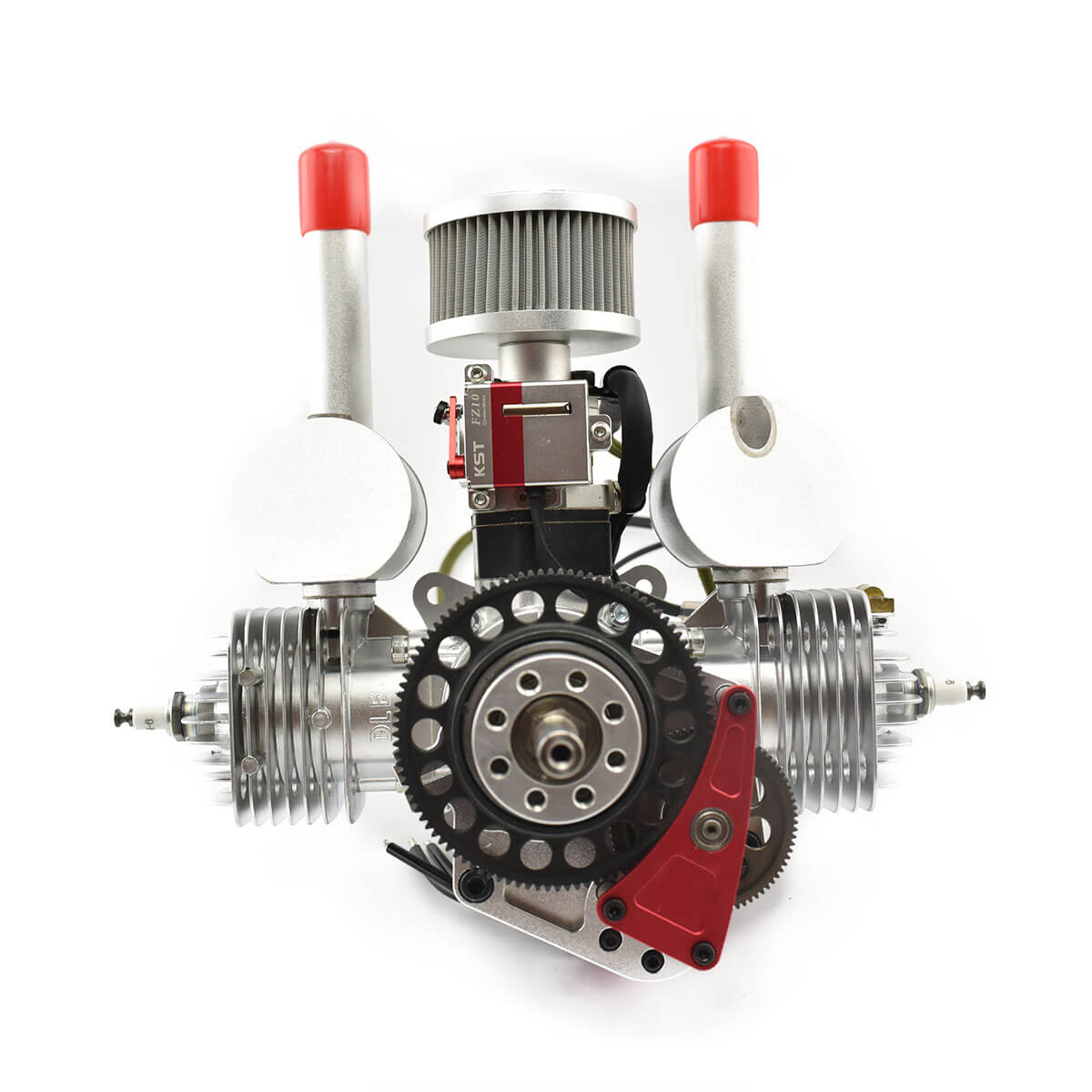

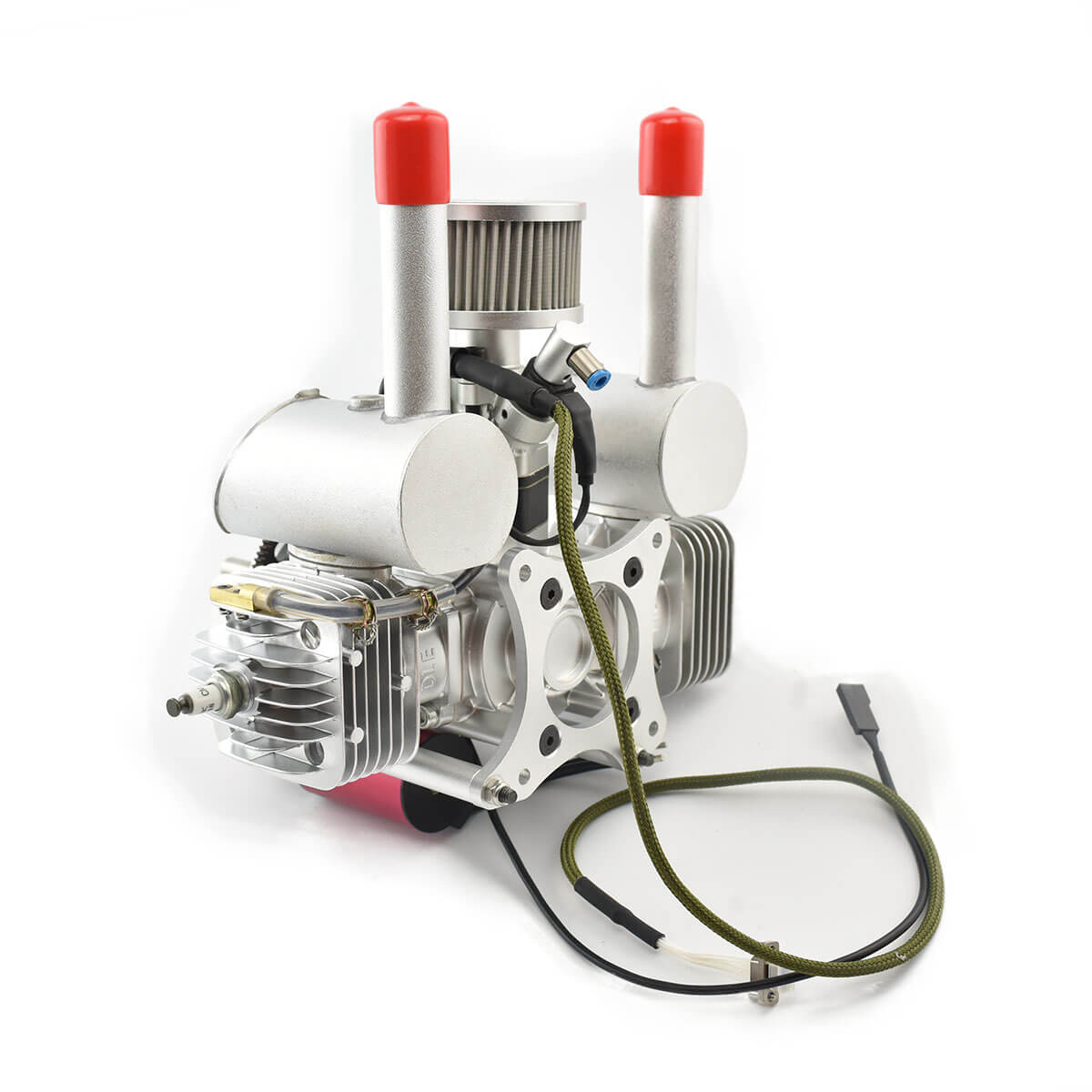

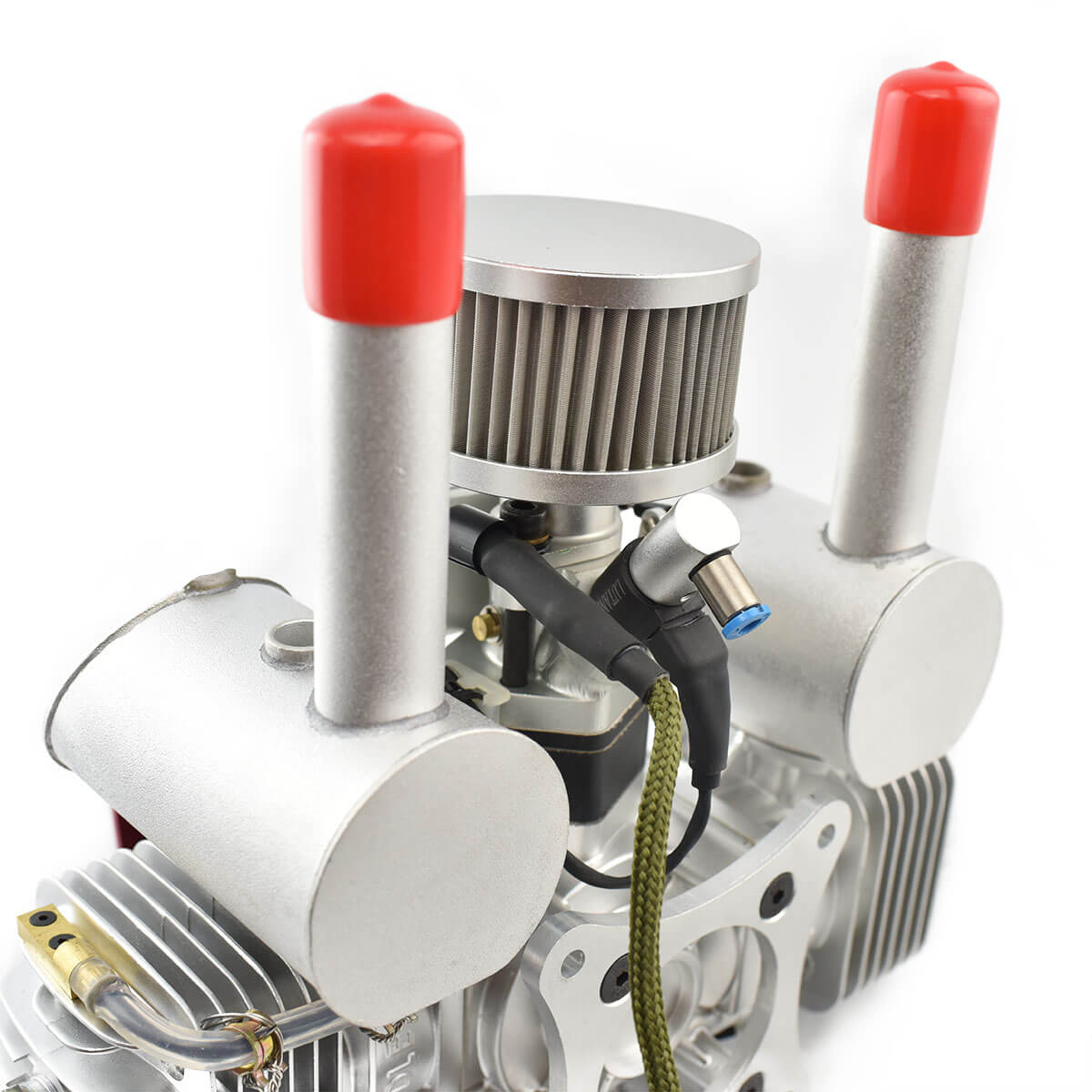

DLE60 now comes with the EFI (Electronic Fuel Injected Engine) version. This EFI engine adopts a parallel-bar horizontally opposed design, which provides higher reliability and power for the drone, and at the same time solves the common shortcomings of two-stroke engines. The newly designed fuel pump has self-priming ability and adopts closed-loop pressure control to precisely control the fuel pressure without returning to the fuel tank. It also provides RS232 communication protocol to obtain engine operation data in real time.

[tx_row]

[tx_column size=”1/2″]

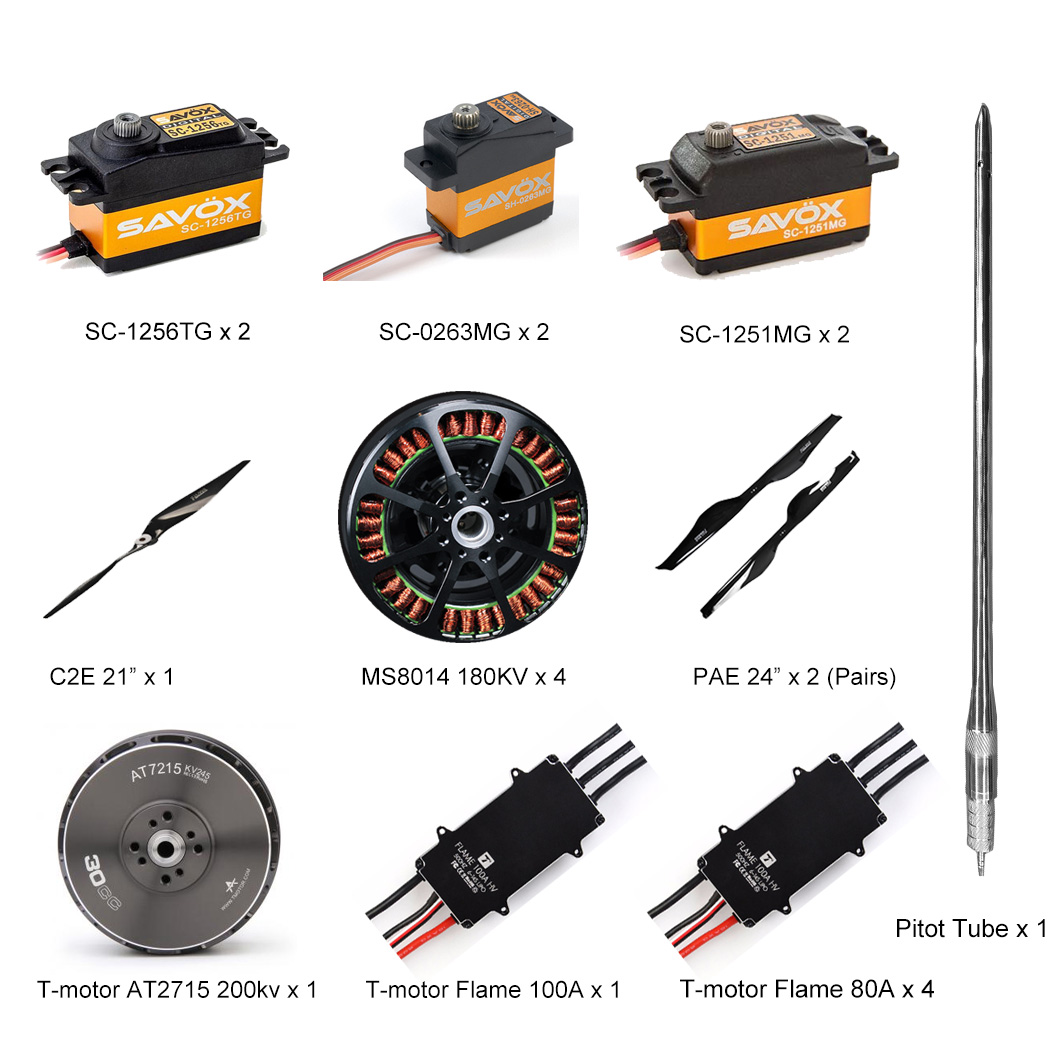

Items Included:

- Engine with Intake Assembly

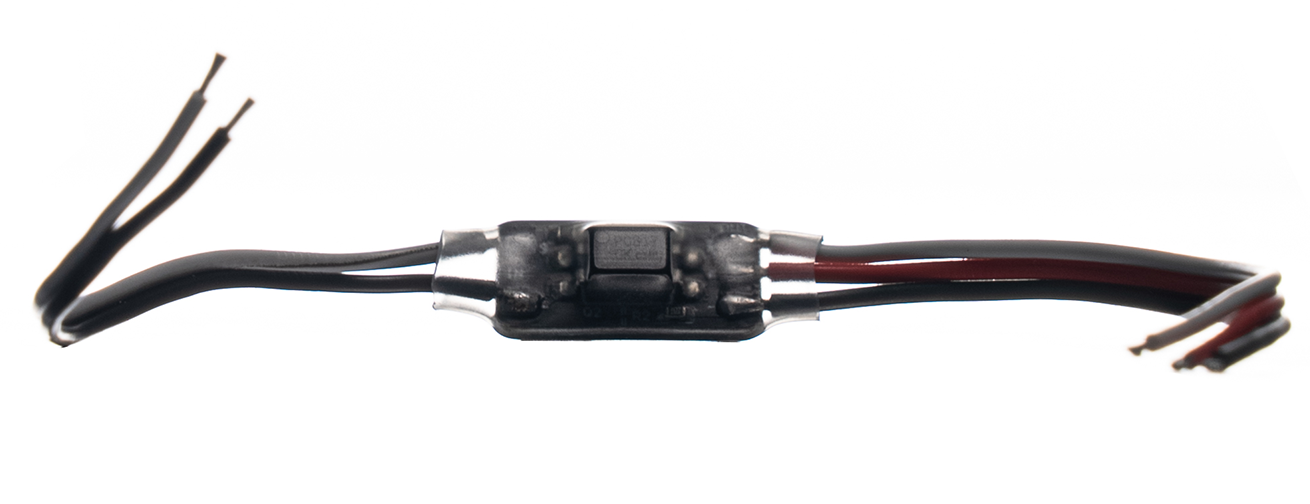

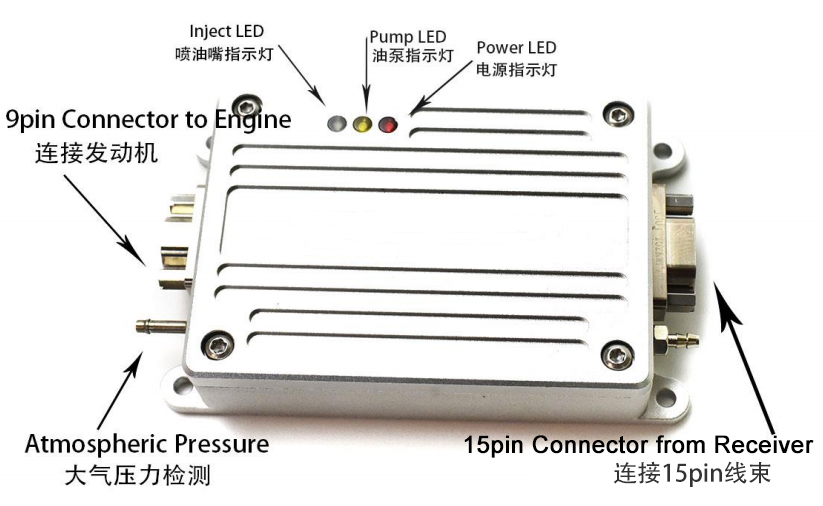

- Engine Control Unit(ECU)

- Engine CDI

- Fuel Pump

- Fuel tubing

- Main Wire Harness

- Engine Assembly Hardware

- Operation Manual

Technical Data:

- Idle: 2300 RPM/M

- Max RPM: 7800 RPM/M

- Thrust: 15KG/100 Meter Altitude

- Propeller Range:22X10;23X8;23X10;23X12;24X10

- Spark Plug: CM-6

Specifications:

- Displacement: 61cc

- Compression Ratio: 7.6:1

- Lubrication Ratio: 40:1

- Weight of the Main Engnine: 1900G

- ECU: 110G

- Fuel Pump: 180G

- CDI: 160G

- Power Waste:12V/4W/2000RPM, 12V/12W/6000RPM

- Output: 24v/48v optional

[/tx_column]

[tx_column size=”1/2″] [/tx_column]

[/tx_column]

[/tx_row]

[tx_row]

[tx_column size=”1/2″]

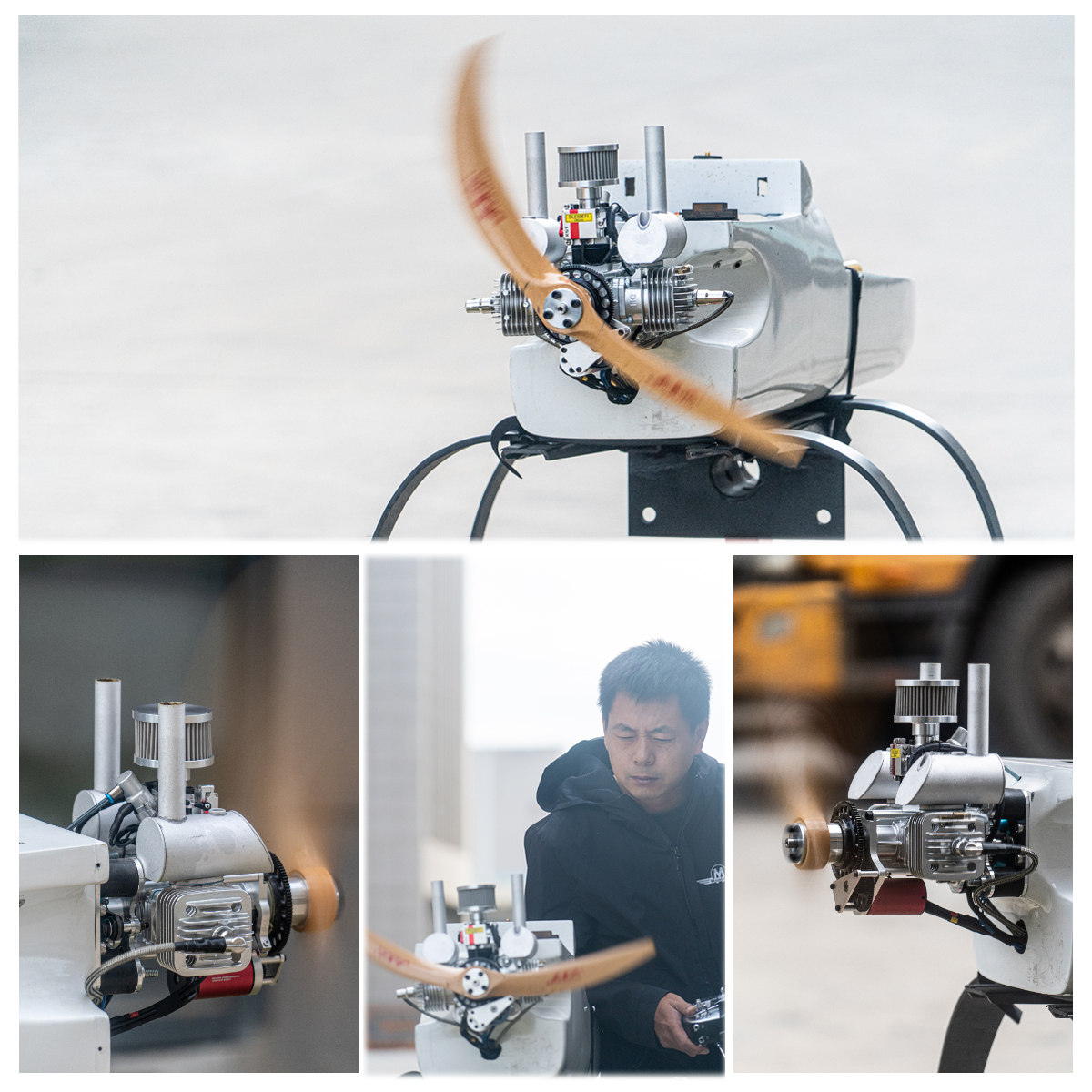

Tips on Engine Installation

- Do not install the ECU, fuel pump and CDI to the engine or motor mount. The vibration will damage the hardware. Route the ECU to a location inside the aircraft and mount it where vibration is minimal. The ECU does not produce excessive heat and can be encapsulated in foam to isolate it from vibration if needed.

- Refer to the diagrams above and make sure wire harness of EFI are well designated & Connected.

- When the engine is mounted, check all the wiring harness are connected correctly & the reliability for the connection. It is necessary to ensure the wiring harness does not rub against the body part.

- When the engine is installed, related shock absorption is required, and screw glue is used to ensure reliable installation.

- Connect the thin fuel line from the output port of the fuel pump to the oil inlet of the throttle valve, push tubing past locking ring in blue to produce a proper seal and lock it, in reverse push the locking ring to release the fuel line (do not fold or twist the fuel line).

- The fuel pump is installed close to the fuel tank. It is recommended not to be higher than the fuel level, and ensure fuel inlet fuel line & fuel outlet fuel line be not bent or folded;

- The thin fuel line connecting fuel pump & the engine should be kept at least 30cm in length in order to reduce fuel pressure change.

- Install the fuel filter between the fuel pump inlet and the fuel tank, ensure the fuel line is connected properly in place; tighten the non-falling nut for fuel line.

- Any 3 Cell Lipo or 4 Cell Lifepo4 or equivalent battery with a minimum of 2000 mAh rating will run the engine for up to 2 continuous hours (5000 RPM/H). DLE60cc engine is the latest version with CDI voltage from 4.8V-14V. Gaskets for DLE engines (Since September 2021) are in the latest material without air pollution restricted by some countries.

[/tx_column]

[tx_column size=”1/2″]

Throttle Setting

- Throttle commands use standard RC TX/RX or flight controller. The voltage of throttle servo installed on the engine is 6V-7.4V by RX or Flight Controller Channel.

- Before starting the engine, adjusting the exponential rate of TX throttle curve or flight controller to get the desired throttle response with throttle air valve, which affects the engine performance.

- Our EFI system does not need extra Throttle Kill Switch, the engine will stop and automatically the power for fuel pump is cut off when throttle air valve is fully off.

- For UAV project with the engine applied, providing power to the enable line of ECU,when the signal of flameout is given, the enable line on an optional module (not recommend) will stop the engine. For most flight controllers on the market, 10{dadd650eeaba6f64f533239c6790b4fc98b2e0cf5f68cfe74cb088220b8d2ab8} rate for idle RPM is set and will not stop the engine until turning off the button on the flight controller. Suggest the user to set up the idle rate on your TX or flight controller for the first time to operate the engine. Properly adjust and set up the throttle curve and rate to avoid the damage of throttle servo by dead steering.

[/tx_column]

[/tx_row]